Slit Die Coater New Taku-Die Specifications

世界最小スリットダイコーター「NEW卓ダイ」で塗工テスト受付中

Slit Die Coater New Taku-Die Specifications

Characteristics

|

Small and Light Savint cost Suction table Easy assemble Die design Simple liquid supply Accurate liquid flow

|

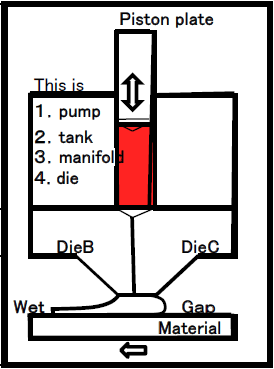

Saving space,removable light weight Min,10cc,no waste expensive coating liquid Opening Dia 5μ , no suction-mark, no dry-spot 3-Die pieces assembling time 15min only Highly presize coating with a lot of die lip design Serving three functions(pump,tank,manifold) Because of Same Width of piston plate and coating width |

Specification

|

Material Coating Width Thickness Viscosity Speed |

Glass,Film,Alm/Copper,Foil,Plastic sheet 2mm~250mm Wet base1μ~1000μ 1~150,000mPa.s 2mm~300mm/sec |

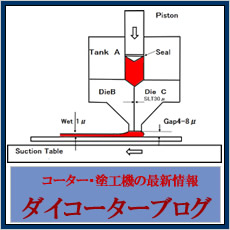

The principle is simple

Apprications

|

Photoresist,Secondary,battery,Organic electoluminescence,Carbon ink,Insulation paint,Water repellent liquid,Super conductive material, Magnetic paint, Thermoplastic resin, Hotmelt resin, Liquid crystalUV curable resin Hard coat, Ceramics Anti-reflection, LR, AG, Adhesive resin |

Options

|

Table Coater Wet On Wet Coating with Bar Double Slit Coating Stripe Coating Intermittent Pattern Simultaneous 2-layer Coating On-Roll Coater One-Roll Coating Two-Rolls Coating Roll-To-Roll Coating with unwinder,winder,dryer |

On-Roll Coater

This coating machine is designed for Web materials. However,liquid supply system and Coating Die Head unit are same concept design with New Taku Die Top feed and Side feed coating both are available.

There are 3 coating stages as below.

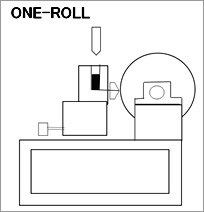

①Stage-1:One Roll Coater |

Winding material on main roll and fix,you can get one roll length coated sample. |

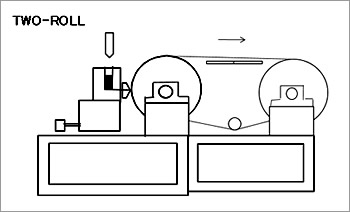

②Stage-2:Two Rolls Coater |

Winding Material on two rolls and fix,you can get more longer length sample than One Roll type. Even easy folw liquid is stable on the material between two rolls |

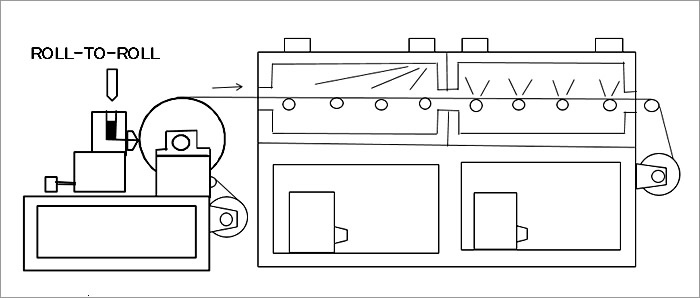

③Stage-3:Roll To Roll Coater |

By addition Unwinder,Dryer and Winder, it become conplete Coater line. |

Specification

| Materials | Plastic film,Metal foil,Paper |

| Materials Width | Ma.300mm |

| Coating Width | Ma.250mm |

| Coating Length | 400mm |

| Coating Speed | 100m/min |