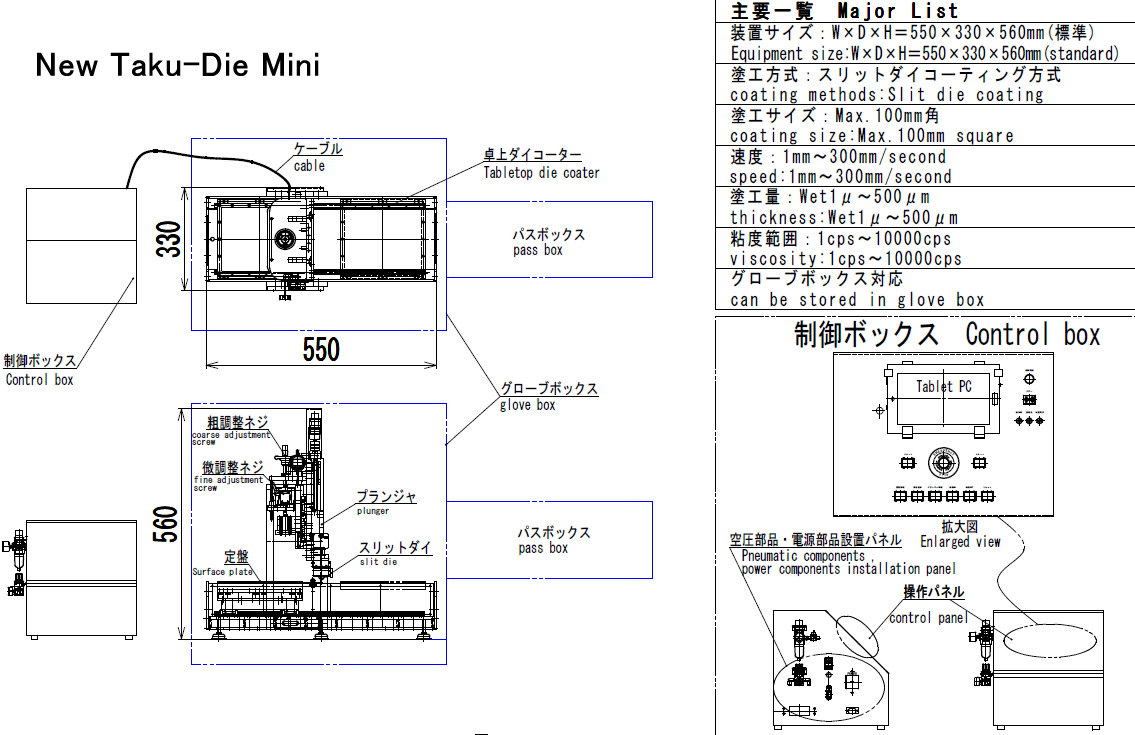

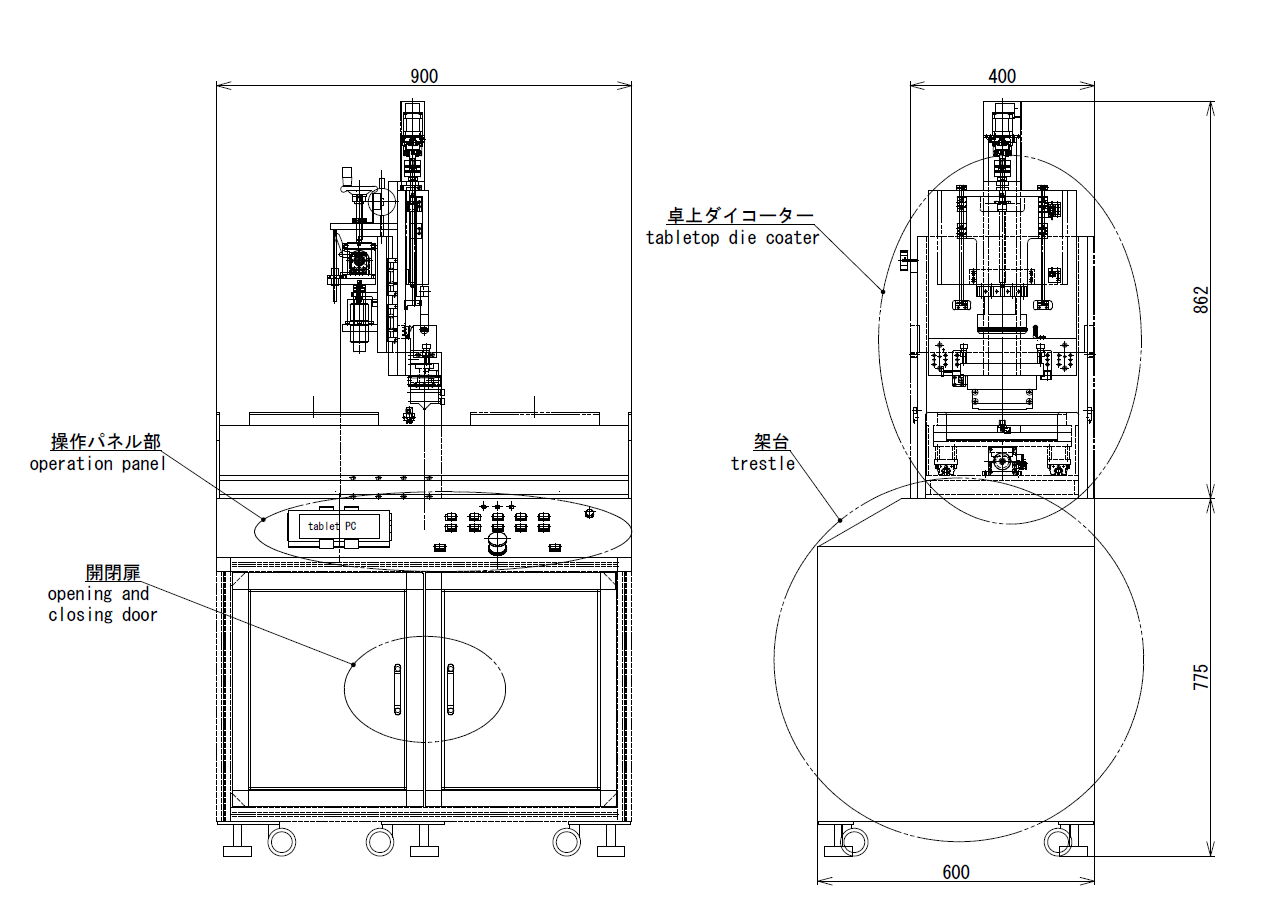

Specification Sheet New Taku-Die S & Mini

世界最小スリットダイコーター「NEW卓ダイ」で塗工テスト受付中

Specification Sheet New Taku-Die S & Mini

A.Rough Specification |

||

1.Style |

Coating St and Control Box are combined in a Body | Coating St is separated from Control Box. |

2.Materials |

Glass, PET Film, Metal Foil,Textile Metal | Ditto to Left side |

3.Material Size |

within 250mm square | over 30mm square、within 120mm square |

4.Coating Width |

50mm-250mm | 25mm-100mm |

5.Coating length |

30mm-300mm | 20mm-150mm |

6.Coating Speed |

1mm-300mm/sec | Ditto |

7.Coating Specification |

||

①Coating methods |

Slit Die | Ditto |

②Coating thickness |

Wet 2μ-1500μ | Wet 2μ-1500μ |

③Viscosity .Range |

1-150,000cps | 1cps-50,000cps |

④Coating solutions |

Solvent, Water base, UV Cure type Hot-Melt type(Option) | Ditto |

8.Utility |

||

①Electric |

100-220V,50-60Hz,Single phase | Ditto |

②Compressed Air |

0.4MPA(consumption 240cc/min) | Unnecessary |

9.Weight |

230kg | Coating St 80kg, Controll Box 20kg |

10.Machine Size |

W900mm × D650mm × H1700mm | W550mm × D330mm × H560mm |

| B.Components | ||

| 1.Coating St | ||

| ①Body | Alm Flame Structure | Ditto |

| Machine leveling bolt, 6positions | Machine leveling bolts, 4positions | |

| With 6 Casters under box for machine movement | without | |

| SUS cover plate around coating St. | Ditto | |

| ②Drive | Stepping Motor | Ditto |

| Rail | Actuator +LM guide | Actuator drive |

| ③Suction Table | Table Size: 300mm square | 150mm square |

| Suction Range:270mm square | 120mm square | |

| Surface Material : Carbon made | Ditto | |

| Suction Hole Dia: about 5μ | Ditto | |

| SUS304 Suport Flame for table | Ditto | |

| Table level adjusting bolts | Ditto | |

| ④Coating Die Unit | ||

| ・Suport methods | Machine side flames support Die Unit | One side flame support Die Unit for easy operation in using Glove Box |

| ・Die unit Up and Down | By Air cylinder | By motor |

| ・Gap rough adjustment | Manual Adjustment rough Gap | Ditto |

| ・Gap fine tuning | Manual Adjustment strict Gap by 1μ with digital Indicator | Ditto |

| ・Die Head | ||

| Die A | Liquid quantity 85cc(Max.300cc) | Min 5cc-85cc |

| Any quantity of solution available(Min10cc) | Suck back solution system | |

| Die B | Lip width 0.5mm-5mm | Ditto |

| Die C | Lip width 0.5mm-2.5mm | Ditto |

| Slit width 30μ-1500μ | Slit width 30μ-500μ | |

| ・SLT 30μ :1cps-20cps | Ditto | |

| ・SLT 100μ:20cps-2000cps | Ditto | |

| ・SLT 500μ:hundreds cps - 10 thousands cps |

Ditto | |

| ・SLT1000μ:thousands cps - 100,000cps |

No | |

| Lip cover with magnet attachment | Ditto | |

| Die Lip Taper 0-0.8° | 0~0.6 | |

| ・Plunger unit up and down | Driven by Stepping motor | Ditto |

| Teflon seal(Inc 3pieces) | Ditto | |

| ・Braket for Die unit | One side Gap changeable by 150μ | Ditto |

| 2.Tablet PC | Input coating condition data located on Control Box | Ditto |

| 3.Operation Desk | Auto-manual buttons, 2-Starting buttons and emergency stop button | On Controll Box |

| 4.Controll Box | Control Unit, Vacuum Pump in Box Main SW, Breaker, Regulator, Pressure SW are installed at side part of machine | Ditto |

| 5.Accessory | ||

| ①Measuring Equipment for suction table |

Measuring flatness of suction table, and adjust it by bolts. | Ditto |

| ②Area sensor | This sensor for not to be nipped finger between table and Die | Ditto |

| 6.Final acceptance | Explanation machine structure,CHK details of machine Instruction of machine operation Free running, Coating Test | Ditto |

| 7.Export packing and | Included | Ditto |

| 8.Super Visor | Leveling machine and Suction-table,free running, coating test Instruction machine operation,2P | Ditto,1P |

| C.Option | ||

| 1.Safety Box | Interlock in opening door Supply/Exhaust window | Ditto |

| 2.Exprosion prove Spec. | Air Purge:Motor,Panel,Wiring Barrier relay:relay | Ditto |

| 3.Cartridge heaters,sensor controller for Die |

4-Heaters, 1-sensor, 1controller | 2-heater, 1-sensor, 1controller |

| 4.Area sensors | 2-Poles at front, or 4-Poles at 4corners | Ditto |

| 5.Coating liquids,supply System | Manual valve, pipe, tank | No |

| 6.Suck back liquid system | Min10cc | Min.5cc |

| D.Two Layer Coating | ||

| 1.Simultaneous 2-layer coating Die | 2motors for 2Plungers | Ditto |

| 2.Wet-On-Wet Die coating stations | Twin coating stations | Ditto |

| E.Out of scope | ||

| 1.Machine base,fixing machine on floor | ||

| 2.Clean specification of machine | ||

| 3.Exhaust equipment | ||

| 4.Machine illumination | ||

| 5.Utility and wiring , piping, ducting works | ||

| 6.Exprosion proof, anti vibration specification | ||

| 7.Specification of User's internal safety regulation | ||

| 8.Material and coating solution for coating test | ||

| 9.Spare parts | ||

| 10.Iron table for Die assembling | ||

| 11.Tools |

| F.General | ||

| 1.Ducmentations | ||

| ①Machine layout drawing | ||

| ②Assemble drawing | ||

| ③Electric wiring drawing | ||

| ④Outside production list | ||

| ⑤Instruction manual | ||

| 2.Warranty | ||

| Die Gate Corp warrant to the original purchaser each product in material and workmanship under | ||

| normal operating conditions for a period 12 months from the date of shipment from Die-Gate Corp. | ||

| Under this warranty the obligation of Die Gate is limited to repairing any product that proves defective | ||

| within the warranty period, if such product are returned to Die Gate with transportation charges | ||

| prepaid. This warranty shall not apply to fuses,lamps, battery and so on, or other items, which are | ||

| expendable due to normal, wear, unless otherwise indicated damage cause by improper operating | ||

| conditions misuse negligence or the alteration or removal of the nameplate will void this warranty. | ||

| 3.Acceptance | ||

| Die-Gate confirm no defect of product appearance, each mechanical movement actual coating in | ||

| the presence of a purchaser in conformity with inspection sheet. | ||

| When all operation training and maintenance explanation are practiced, this product is considered | ||

| "ACCEPTANCE". | ||

| Die Gate doesn't guarantee coating accuracy be cause of many kinds of factors to influence it, but | ||

| guarantee Mechanical accuracy of Coating Die and Flatness of Suction Table. | ||

New Taku-Die S

New卓ダイMini(塗工幅20mm-100mm)